The Role of IIoT Devices in Creating Smart Factories Enhancing Connectivity and Efficiency

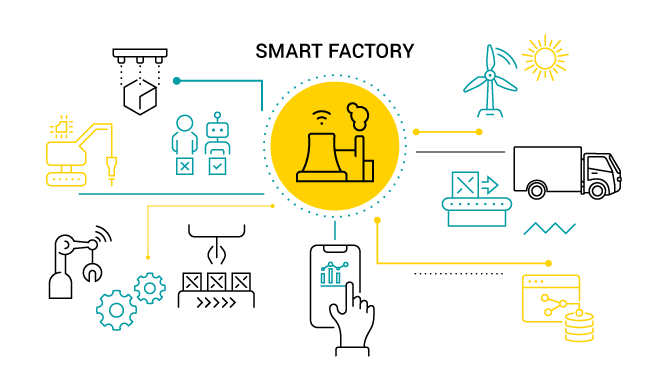

In the era of Industry 4.0, the integration of technology into manufacturing processes has given rise to the concept of smart factories. At the heart of this industrial revolution is the Industrial Internet of Things (IIoT), a network of interconnected devices that play a pivotal role in transforming traditional manufacturing units into highly efficient and connected ecosystems. This blog explores the significant role of IIoT devices in the creation of smart factories, emphasizing their impact on connectivity and overall operational efficiency.

- Connectivity Redefined

Traditional manufacturing setups often operated in silos with limited communication between different processes and machinery. The advent of IIoT devices has revolutionized connectivity by enabling seamless communication and data exchange among various components of the manufacturing chain. Smart factories leverage the power of interconnected devices to create a network where machines, systems, and even personnel can communicate in real-time, fostering a more agile and responsive manufacturing environment.

- Real-Time Monitoring and Data Analytics

One of the primary contributions of IIoT devices to smart factories is the ability to provide real-time monitoring and data analytics. Sensors and connected devices collect a wealth of data from manufacturing processes, equipment, and even the surrounding environment. This data is then analyzed to gain valuable insights into operational performance, identify inefficiencies, and predict potential maintenance issues. The result is a proactive approach to decision-making that enhances overall efficiency and reduces downtime.

- Predictive Maintenance for Enhanced Efficiency

IIoT-enabled devices facilitate predictive maintenance strategies, a game-changer for manufacturing efficiency. Through continuous monitoring of equipment and machinery, these devices can predict when maintenance is required, helping organizations move from reactive to proactive maintenance practices. This not only extends the lifespan of machinery but also minimizes unplanned downtime, reducing operational disruptions and boosting overall productivity.

- Supply Chain Optimization

Smart factories are not limited to the shop floor; they extend their connectivity to the entire supply chain. IIoT devices enable manufacturers to gain real-time insights into the movement of raw materials, work-in-progress inventory, and finished goods. This heightened visibility allows for better inventory management, reduced lead times, and improved coordination with suppliers and distributors. As a result, the entire supply chain becomes more responsive and adaptable to dynamic market conditions.

- Enhanced Energy Management

Sustainability is a key focus for modern manufacturing, and IIoT devices contribute significantly to enhanced energy management in smart factories. Connected sensors monitor energy consumption in real-time, identifying areas of inefficiency and opportunities for optimization. This data-driven approach enables manufacturers to implement energy-saving measures, reduce costs, and contribute to environmental conservation.

- Empowering Human-Machine Collaboration

While IoT devices automate many processes, they also empower human-machine collaboration within smart factories. Employees can leverage real-time data and insights provided by connected devices to make informed decisions, troubleshoot issues, and contribute to continuous improvement. This collaborative approach enhances overall operational intelligence and creates a work environment where humans and machines complement each other.

The integration of IIoT devices is the cornerstone of the evolution towards smart factories, marking a significant shift in the manufacturing landscape. By enhancing connectivity, enabling real-time monitoring, and optimizing various aspects of operations, IoT devices play a pivotal role in creating highly efficient and responsive manufacturing ecosystems. As industries continue to embrace the transformative power of IIoT, the vision of smart factories as the future of manufacturing becomes increasingly tangible.

As a trusted distributor of TIBBO Technologies (Taiwan) products in India, THETA SALES & SERVICE is proud to bring cutting-edge industrial solutions to businesses across the country. Specializing in a range of products, including serial converters and embedded programming modules, TIBBO's offerings are at the forefront of technology and innovation.

At THETA, we offer a diverse selection of industrial devices designed to revolutionize the way businesses operate. Our partnership with TIBBO Technology allows us to provide state-of-the-art IoT devices and units, along with essential development tools. These offerings are crafted to enhance operational efficiency, optimize processes, and elevate productivity to unprecedented levels.

We also offer Thyristor controllers, Paperless Recorder, Temperature transmitters, Digital Timer Temperature Control Systems, and Accessories.

Call us for more deatils